NEIEP Spotlights Virtual Hydraulic Controller Lab (VHCL) Troubleshooting Course

A methodical approach to troubleshooting is one of the most valuable skills an Elevator Mechanic can develop. It provides structure for solving problems, saving time, reducing stress, and reinforcing confidence on the job. Once mastered, good troubleshooting habits become second nature, as essential to your toolkit as a meter or wrench.

To help Elevator Apprentices and Elevator Mechanics strengthen these skills, NEIEP offers the Virtual Hydraulic Controller Lab (VHCL) Troubleshooting Course. For Elevator Mechanics, the course is available as CE043 on the Online Training & Licensing page at neiep.org. For Elevator Apprentices, the course is also an integral component of the RC700 curriculum.

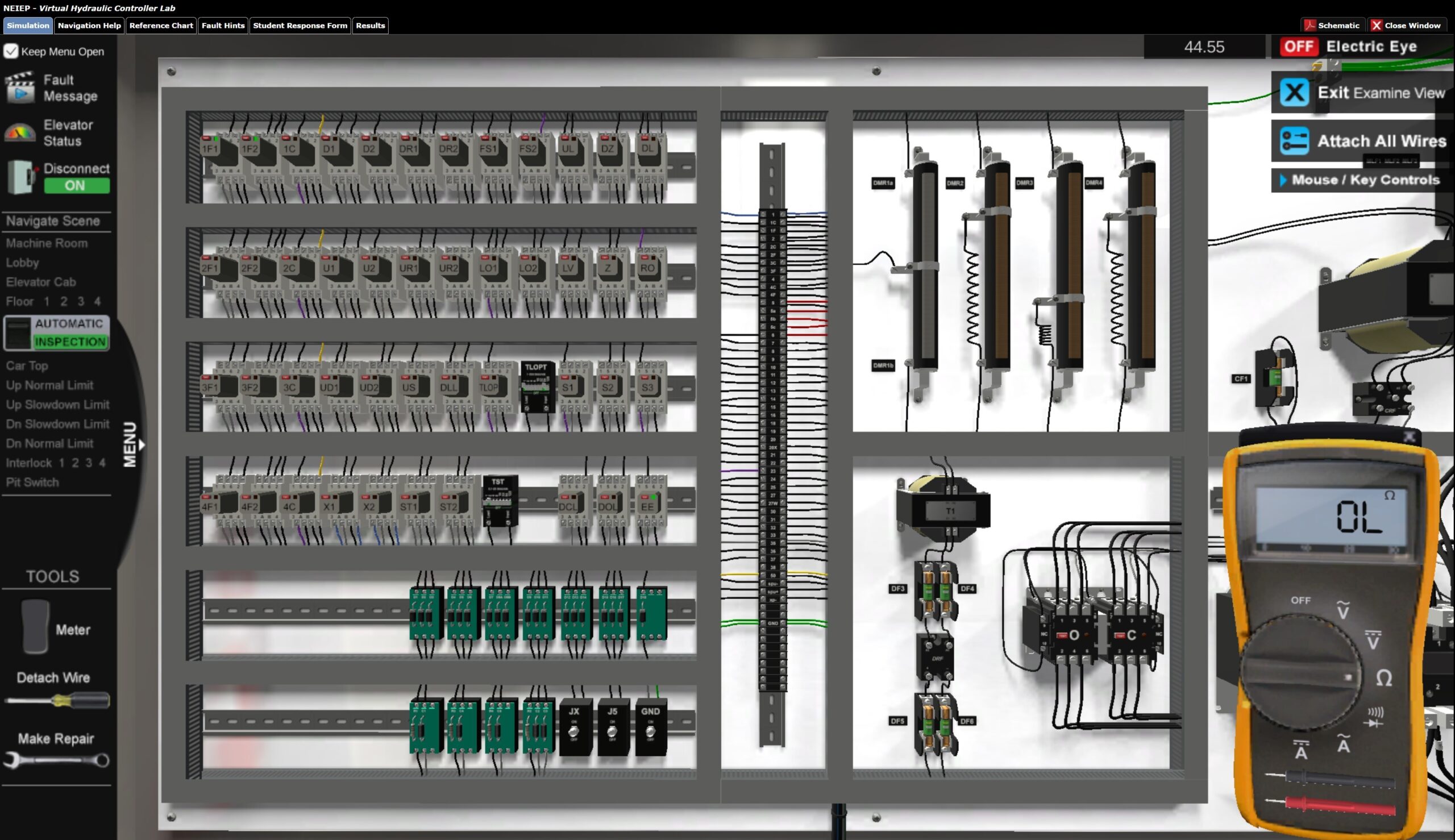

The VHCL provides a guided, hands-on study of troubleshooting techniques using the NEIEP 4-Stop Hydraulic Controller Simulation Environment. Within this virtual lab, students encounter distinct fault scenarios, each one representing a separate trouble call that requires a logical diagnostic process to locate and correct the fault.

A Realistic Virtual Learning Environment

The VHCL is designed as a detailed digital replica of NEIEP’s well-known physical Hydraulic Controller Lab (HCL) suitcase unit. The virtual controller reproduces all components of a physical elevator, allowing students to practice in a lifelike simulation of an actual elevator control system.

The VHCL simulation is divided into four major environments, each representing a key area commonly found on a hydraulic elevator jobsite:

- Lobbies

- In-Car

- Machine Room

- Car Top

Each area includes examine views, accessed by clicking on blue rotating diamonds within the interface. Once inside an examine view, a digital meter is available for checking voltages, continuity, and circuit conditions, just as these tools would do in the field. The result is an immersive, hands-on training experience that blends the accessibility of online learning with the realism of on-the-job troubleshooting.

Fundamental Troubleshooting Methods

The VHCL Troubleshooting Course aims to build a structured and consistent method for solving electrical problems. Designed to be as intuitive as possible, the lab begins with a sequence of exercises that guides students through the operation of a functional hydraulic elevator equipped with a collective controller. While completing this section of the course in preparation for the virtual environment, students are introduced to four fundamental troubleshooting methods, each representing a different approach to analyzing and diagnosing control circuits.

1. Logical Reasoning and Circuit Analysis

The first method focuses on mental analysis: reviewing the circuit diagram, visualizing current flow, and predicting how components interact. This method is vital in helping students narrow down possible causes before conducting any physical tests.

2. Troubleshooting from a Common Point on an Energized Circuit

This method teaches students how to measure voltage potential using a fixed common point of reference on an energized circuit. They learn to use the half-split method, which helps isolate faults efficiently, and techniques for measuring voltage across individual contacts. The course also helps students recognize common pitfalls, including how multiple contact failures can produce misleading voltage readings.

3. Troubleshooting from a Common Point on a De-Energized Circuit

In method number three, students learn to verify circuit conditions from the left common line, checking continuity and coil integrity without moving the common reference point. The half-split makes an appearance here, too, demonstrating how a logical testing order can reduce the number of checks needed to identify an open connection or failed component.

4. Changing the Common Point of Reference

The fourth and final method introduces a more advanced technique: changing the common reference point to troubleshoot circuits that contain contacts on both sides of the load. This approach reinforces the importance of adaptability and circuit understanding, particularly when dealing with complex relay logic systems.

Breaking Down the Logic Functions

CE043 is organized into eight separate but interconnected logic functions. Each section focuses on one set of circuits, exploring how they work together to create a fully operational elevator control system.

The eight logic function sections that prepare students for troubleshooting faults in the virtual environment are as follows:

- Power Control

- Selector Circuits

- Call Registration

- Direction Selection

- Starting and Acceleration

- Stopping

- Door Operation

- Call Cancellation

When it comes to instruction, each logic section follows a consistent pattern:

- Animated circuit diagrams with narration guide students through how each logic function works.

- Observation sessions let students watch the virtual lab in normal operation, using the course text to follow along.

- Reference charts are provided for recording voltage, resistance, timing, or other test data.

- Targeted faults are inserted into each logic section, challenging students to apply their diagnostic methods to solve realistic problems.

After working through each logic function, students will face a final assessment that includes several randomized faults presented in the virtual environment. These final assessments require minimal guidance, mirroring the independence and analytical thinking required of Elevator Mechanics.

Register Today

NEIEP’s Virtual Hydraulic Troubleshooting Course is available now and open to all interested learners who want to challenge themselves, explore the inner workings of elevator control systems, and sharpen their diagnostic abilities. To get started, visit the Online Training and Licensing page at neiep.org. Scroll to the bottom of the Continuing Education (CE) course list and select CE043 – Virtual HCL. For Elevator Apprentices, you can look forward to tackling the VHCL Troubleshooting Course in RC700.