NEIEP Releases Revised RC500 Installation Curriculum

While the foundational principles of elevator installation have remained consistent over the years, the tools, systems, and jobsite conditions that modern elevator professionals encounter are evolving rapidly. In response to this shift, NEIEP has updated its core semester course, RC500 – Installation.

This curriculum update reflects NEIEP’s ongoing commitment to providing the most relevant, rigorous, and forward-looking training in the industry. With new content, refreshed visuals, updated tools and terminology, and an entirely new homework interface, RC500 has been comprehensively modernized to help Elevator Apprentices face the challenges, both old and new, of the modern jobsite.

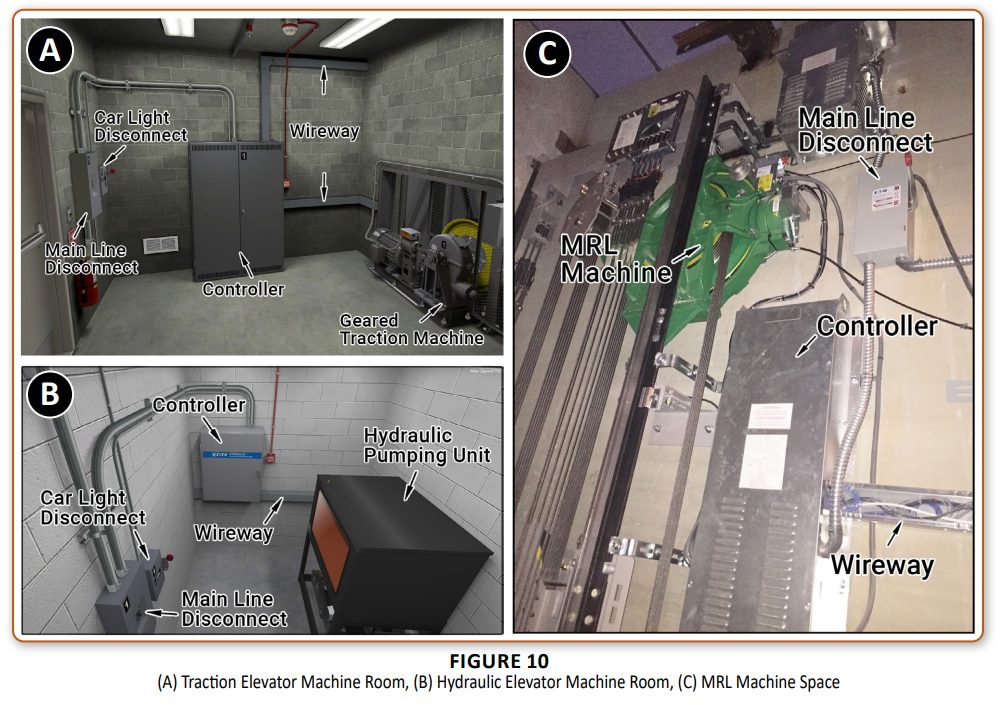

Modern elevator systems rely more heavily on digital communication networks, energy-efficient technologies, and new configurations like machine-room-less (MRL) systems. Nowadays, Apprentices and Mechanics must navigate an increasing number of safety and environmental regulations, while keeping pace with changes to equipment, wiring, and temporary operations.

The RC500 update ensures that NEIEP training reflects the modern realities of working as an Elevator Constructor. During their time studying installation at NEIEP, Apprentices will not just learn how to install an elevator, but also why today’s systems work the way they do and how they must be worked on safely and efficiently.

New Units Added to Strengthen Core Skills

RC500 now includes four new instructional units. Each one addresses areas that have become increasingly central to modern elevator work:

- Unit 515 – Traveling Cables

This unit focuses exclusively on traveling cables, which are critical to elevator operation and safety. Apprentices learn the purpose and construction of traveling cables, how to install and protect them properly, and how to recognize and safely replace damaged components. - Unit 530 – Car Raceway and Wiring

This consolidated unit brings together previously separate content on car wiring, culminating in a more focused and coherent structure. Topics include raceway installation, proper grounding, managing noise and vibration, and the separation of high- and low-voltage systems. - Unit 540 – Asbestos, Silica, and Radio Frequency Awareness

Building upon existing content about asbestos, this expanded unit introduces Apprentices to the health hazards posed by silica dust and radio frequency (RF) exposure, both of which are common risks in modern installation environments. Emphasis is placed on hazard recognition, safe work practices, and regulatory compliance. - Unit 550 – Cab Modernization

This unit teaches the primary skills and key safety procedures required to safely upgrade elevator cabs, including refinishing walls and floors, replacing ceiling panels, and making ADA-compliant modifications. Unit 550 prepares Apprentices to participate in modernization projects with professionalism and precision.

Redesigned Visual Content

Another enhancement to RC500 is the full redesign of diagrams, figures, and illustrations. Clearer, more detailed visual graphics support learning and comprehension, particularly in areas involving intricate physical systems or new technology. These visual updates aim to better reflect current field conditions, tool designs, and layout conventions.

Emphasizing MRL and Temporary Operations

NEIEP has expanded applicable RC500 content to ensure MRL-specific procedures, components, and safety considerations are all covered thoroughly. From hoistway layouts to control systems, Apprentices are now better equipped to work on this widely adopted configuration.

The curriculum also devotes more attention to temporary operations and startup procedures, ensuring that Apprentices understand how to safely and correctly prepare a system for testing and turnover. This content prepares learners for real-world challenges where precision and proper sequencing are essential.

Keeping Up with Evolving Technology

Installation work today requires familiarity with new types of cabling and system communication. The revamped RC500 course content includes expanded instruction on Ethernet, fiber optic, and coaxial cable installation, each of which presents unique challenges in elevator systems. Apprentices are trained not just in how to physically install these cables, but also in understanding their function, compatibility, and best practices for reliability and longevity.

Supporting Student Success: A New Homework Experience

One truly transformative element of the RC500 update is the transition to a more interactive, LMS-integrated homework experience. Previously hosted directly on the NEIEP website, homework assignments for RC500 will now live within NEIEP’s Learning Management System (LMS). This change is designed to encourage deeper engagement and reinforce weekly instruction.

Key Features of the New Homework Format

- Weekly, open-book, multiple-choice assignments aligned with unit texts

- Immediate feedback including correct answers and explanations

- Built-in study tool to support unit review and exam preparation

The goal of the new homework format is to encourage students to engage with the material before coming to class, leading to better questions, deeper understanding, and more meaningful hands-on instruction.

A Future-Focused Mindset

At its core, the RC500 update is about providing the best possible training to Apprentices. Whether they’re just entering the trade or advancing their skills through continuing education, NEIEP learners can trust that their training reflects the most current standards, tools, and expectations.

As new systems and technologies continue to emerge, NEIEP is determined to keep its curriculum responsive, practical, and aligned with industry needs.

To learn more about RC500 and other semester courses that support Apprentice and Mechanic development, visit: NEIEP Apprenticeship Course Catalog.

If you’re interested in learning about the continuing education (CE) courses available, visit: NEIEP Continuing Education Course Catalog.