The Hierarchy of Controls: Protecting Elevator Constructors from the Ground Up

The Hierarchy of Controls is central to the way Elevator Constructors do their jobs. More than just a safety model, this hierarchy shapes several stages of decision-making on the jobsite, from hazard assessment to planning to real-time response on the job. As anyone who has worked in the field will know, the safest jobsite is one where hazards are anticipated, evaluated, and controlled before they can cause harm.

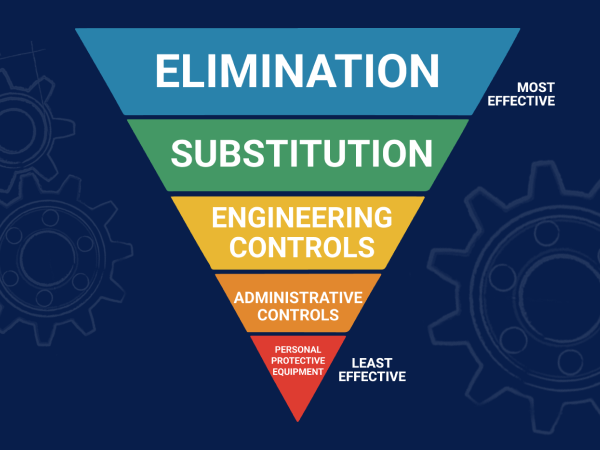

The Hierarchy of Controls is a widely accepted framework for managing workplace risks by prioritizing solutions based on their effectiveness. Adopted by the Occupational Safety and Health Administration (OSHA), the model ranks control strategies in descending order of reliability: elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE). NEIEP teaches this approach to help Apprentices and Mechanics build habits that lead to safe outcomes.

Understanding the Levels of Control

From new Apprentices to seasoned Mechanics, the idea of the Hierarchy of Controls is to start at the top—where controls are most effective—and only move down the list when additional protective options aren’t feasible. Let’s take a closer look at each level in the hierarchy and how it applies directly to the work Elevator Constructors do every day.

Elimination

The first control is elimination, which involves completely removing a hazard from a jobsite. This could be choosing a different installation method that doesn’t require exposure to a fall risk, or scheduling work in a way that avoids entering a hazardous area altogether. For example, in NEIEP’s core semester course, RC500 (Installation), Apprentices learn that the most effective protection from asbestos and silica begins with identifying hazardous materials and removing them from the equation before work begins. While elimination isn’t always possible, especially in environments where legacy equipment or confined spaces are involved, it remains the gold standard for risk reduction.

Substitution

The next level in the Hierarchy of Controls is substitution, which involves replacing a hazardous process or material with a safer alternative. In practical terms, that could mean opting for tools that generate less dust, or selecting chemicals with lower toxicity when cleaning components. Substitution may not eliminate a risk entirely, and it still requires thoughtful implementation, but it represents a proactive choice to reduce hazards at the source. Apprentices learn to recognize these opportunities during job planning as part of risk assessments or Job Hazard Analyses (JHAs), which are thoroughly covered.

Engineering Controls

When substitution and elimination are not feasible, engineering controls come into play. This can include redesigning equipment or processes to isolate workers from hazards. On a jobsite, this could mean installing fixed barriers around open shafts, using ventilation systems in machine rooms, or employing Lockout/Tagout (LOTO). Engineering controls are powerful because they reduce dependence on human behavior, protecting all workers consistently once installed. NEIEP labs give students first-hand experience with these systems, helping them understand how they work and why they are prioritized over procedural solutions.

Administrative Controls

The next tier is occupied by administrative controls. This includes policies, procedures, and training designed to minimize exposure. Some examples include scheduling work to avoid peak traffic times, rotating tasks among team members to limit fatigue, posting clear warning signs, and enforcing rest periods during high-heat operations. A step down in reliability from engineering controls, they are essential when physical changes to the jobsite are not possible. NEIEP reinforces these practices during training and classroom discussion, covering topics that include emergency procedures and evacuation planning.

Personal Protective Equipment (PPE)

The final rung on this ladder is where we find personal protective equipment (PPE), the last line of defense when working on a potentially hazardous jobsite. Helmets, gloves, harnesses, and high-visibility vests are all critical tools, but their effectiveness depends on proper selection, fit, maintenance, and consistent use. PPE is a requirement, regardless of hazards, so it is often used in combination with other methods, particularly in high-risk environments such as hoistways or machine rooms where complete hazard removal isn’t possible.

The strength of the Hierarchy of Controls lies in this progression. Whether working with power tools, handling hazardous materials, or performing maintenance in confined spaces, this model provides a consistent way to prioritize safety to all Elevator Constructors.

Putting the Hierarchy into Practice

The Hierarchy of Controls teaches workers to look beyond what’s most convenient in the moment and to prioritize what’s most effective. This mindset will ensure workers begin at the top of the list and work down only as necessary. In practice, it often requires a combination of controls. For example, an Elevator Constructor working on a high-rise modernization project will likely encounter electrical, fall, and chemical hazards all at once.

In these situations, the safest approach is to implement elimination where possible, physical safeguards where necessary, and administrative support systems and PPE to fill any remaining gaps. Workers should never move on to the next potential solution before exhausting the previous one. If you want to learn more, take a look at this helpful guide from OSHA on applying the Hierarchy of Controls.

Why The Hierarchy of Controls Matters in the Elevator Trade

For Elevator Constructors, the Hierarchy of Controls is more than a chart. It represents a way of thinking that helps them protect themselves and their coworkers from the variety of hazards that they frequently encounter on the jobsite. By anchoring decisions according to this framework, professionals are better equipped to identify the safest option, plan with intention, and step in when safety may be compromised. This framework saves lives, prevents injuries, and reinforces the professional standards that elevate the entire elevator trade.